Dana 60 Ring And Pinion Installation Instructions

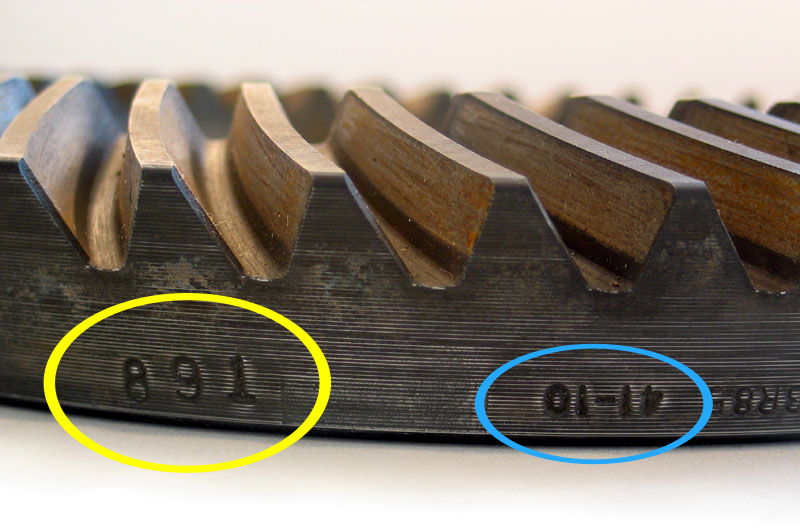

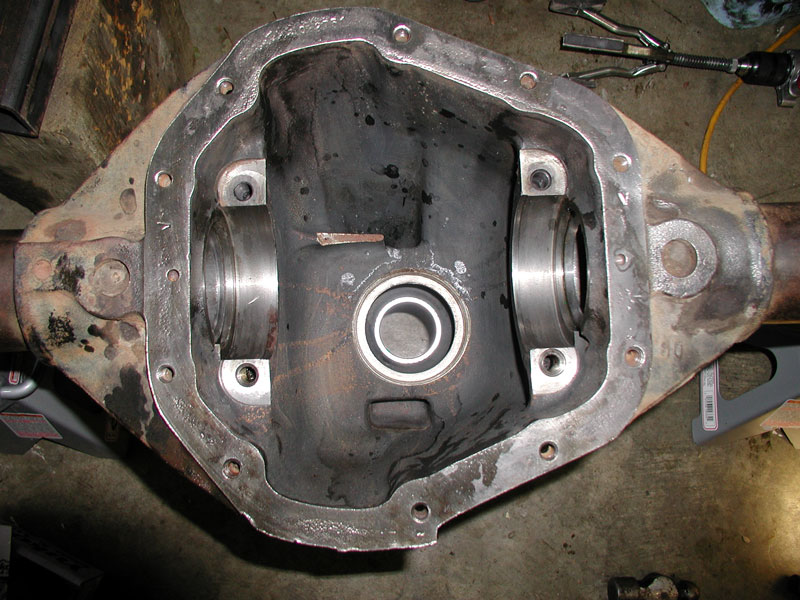

See illustrations a and b.

Dana 60 ring and pinion installation instructions. The job being done. Torque specs for the dana 60 are 120 ft lbs. Pinion depth checker kits proform http amzn to 2a. Eaton performance ring pinion installation instructions.

Dana 44 and 60 rear axle housings establish pinion depth by placing a shim underneath the large inner pinion bearing race. Knock the pinion gear out to the rear with a brass punch taking care not to damage the threads. Ring and pinion gears are designed to be set up and run with exact tolerances. On this episode i go over how to install ring and pinion gears in a ford 8 8 rear end.

Ring gear and pinion tooth pattern interpretation. Then loctite the pinion nut and tighten to 15 inch pounds rotating torque with used bearings or 25 inch pounds with new bearings. When setting the pinion position many of the service manuals required a final pinion position check by using gauges that verified the dimension from the center line of the differential carrier center line of ring gear to the face of the pinion button. During the ring pinion installation there are four pr imary adjustments that will need to be made.

5 once the pinion depth is achieved install a new crush collar preload shim pack for dana s and seal. This is adjusted by adding or subtracting shims to the inner pinion bearing. Hope you dig it. Install ring gear bolts with a six point socket and torque.

If you re changing the ring and pinion or the pinion bearings remove the pinion nut with an air gun while holding the yoke or use a long breaker bar and brace the yoke bolt it to a long board so that it can t move. Pinion depth the distance from the face of the pinion gear to the centerline of the ring gear. Dana 60 arb and ring and pinion installation. 6 with the pinion gear installed position ring.

Gleason gear design manuals dana spicer instruction manuals technical bulletins and general motors repair manuals. This often requires driving in and removing the race more than once. Dana 60 110 85 ford 8 70 50 60 ford 8 8 70 70 85 ford super 8 8 irs 97 102 76 89 ford 9 70 120 80 90 gm 8 4 65 60 gm 8 6 60 65 gm 12 bolt 8 875 45 60 65 fastener choice affects the amount of torque that can be applied.